The stud-and-tube coupling system is the foundational design principle that enables all modern LEGO bricks to interlock securely. Patented in 1958, this ingenious system provides the "clutch power" that holds models together while still allowing them to be easily taken apart.

How the System Works

The stud-and-tube system works through a simple yet precise friction fit:

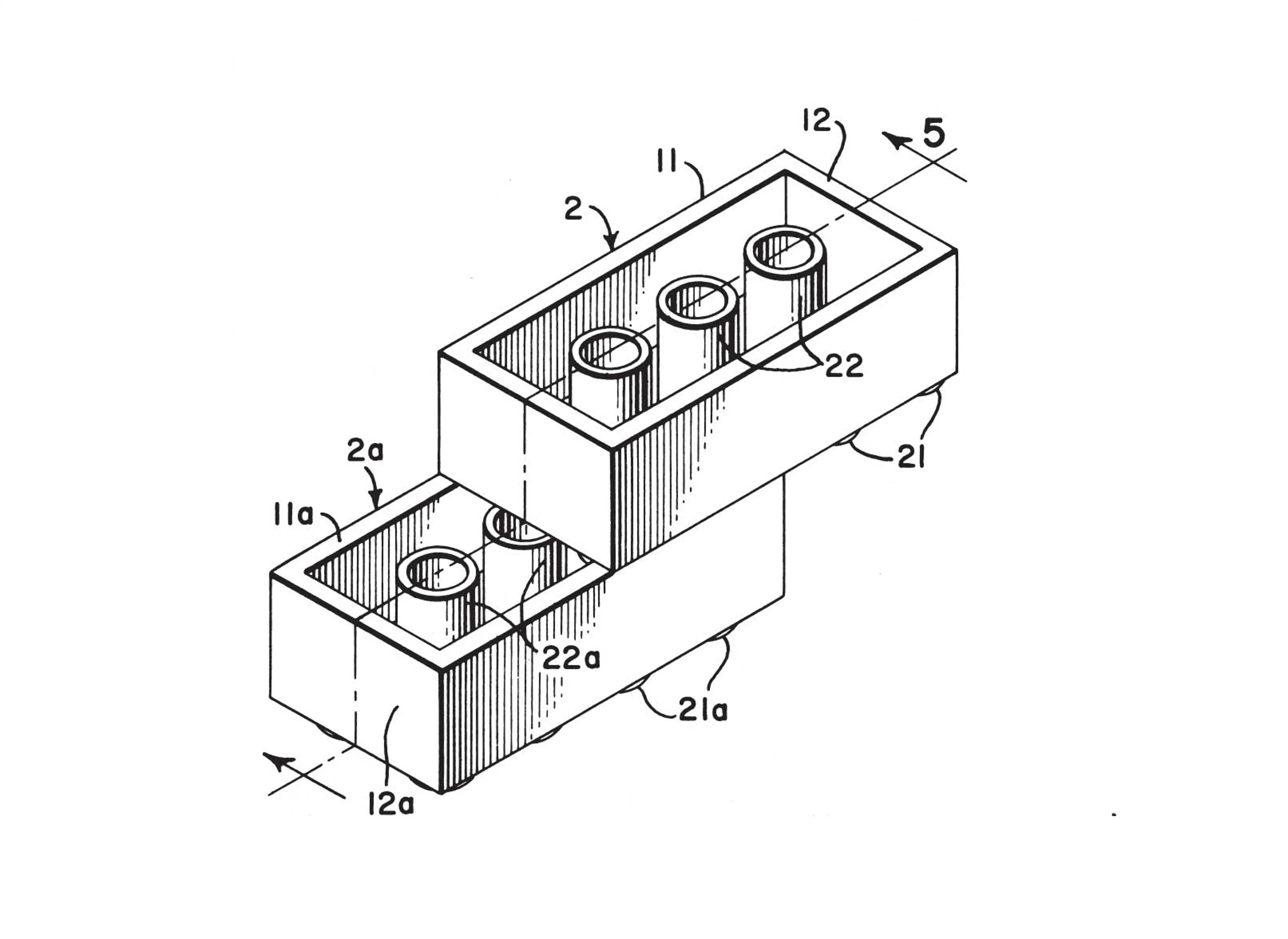

Studs: The top of every standard LEGO brick features cylindrical "studs" (the nubs you see).

Tubes: The underside of a LEGO brick contains hollow cylindrical "tubes" directly beneath the corresponding studs on top.

The Fit: When one brick is placed on top of another, the studs of the top brick fit snugly inside the tubes of the bottom brick.

The precise dimensions of the bricks and the slight "give" in the plastic create friction (clutch power), which holds the pieces together securely.

Key Benefits of the Design

The stud-and-tube system is the foundation of the entire LEGO System of Play:

Compatibility: All standard LEGO bricks made since 1958 are designed to fit together, regardless of color or theme (with the exception of DUPLO, which has its own scaled-up, compatible system).

Stability: The internal tubes provide structural integrity to the bricks, preventing them from warping and ensuring a consistent, strong connection.

Versatility: This simple connection method allows for bricks to be joined in thousands of combinations, enabling virtually limitless creative building.

Precision Engineering: The system relies on extremely tight manufacturing tolerances (measured in micrometers, or millionths of a meter) to ensure every piece fits perfectly every time.

The invention of the stud-and-tube coupling system is considered one of the most important patents in the toy industry and the core reason for the LEGO brick's enduring success.